Opening a Traditional Brewery vs. a HausCraft System

Traditional Brewery

Brewery Opening Cost by Square Foot

Opening a traditional brewery requires substantial space, especially if you plan to include a taproom for on-site enjoyment of your brews. Whether building from scratch, converting a restaurant or retail space, or setting up a beer garden, you can expect to pay between $200-$500 per square foot.

Commercial Brewing Equipment

Equipment represents the largest initial expense. Costs vary widely based on the brewery size:

• Microbrewery systems (3-7 barrels): $70,000 – $200,000

• Medium-sized craft brewery systems (10-30 barrels): $275,000 – $1.3 million

• Large breweries: Startup costs can reach up to $3 million

Essential Equipment Includes:

• Mash/lauter tun: Infuses grains and water to create wort.

• Brew kettle: Boils wort.

• Heat exchangers: Quickly cools wort.

• Fermentation tank: Holds wort during fermentation.

• Brite tank: Clarifies and carbonates beer.

• Kegs, cans, or bottles: For storing and distributing beer.

Staffing Costs

Common roles and average salaries:

• Head Brewer/Assistant Brewmaster: $72,556 annually

• Marketing Event Coordinator: $51,142 annually

• Packaging Operator I (Entry): $23.63 per hour

• Operations/Production Manager/Director: $115,528 annually

• Tasting Room Assistant Manager: $58,294 annually

Barriers to Producing Craft Beer are Eliminated - including the high costs!

A Turn-key Microbrewery

HausCraftBeer’s advanced patented technology significantly reduces capital and operating costs, enhancing profit margins. We provide ready-to-ferment dried wort, eliminating the need for a mash/lauter tun, brew kettle, or heat exchanger. This reduction in equipment lowers space requirements, making it ideal for locations with limited space like restaurants, bars, and casinos.

Scalable and Modular

The HausCraftBeer system is modular and scalable, with some operators using 4 and 6 tank systems.

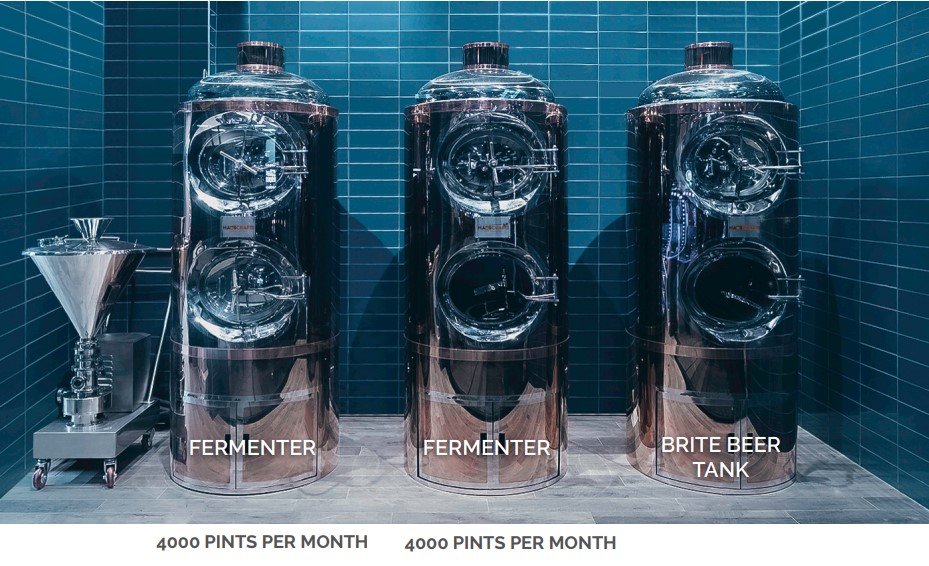

Basic 3-Tank HausCraftBeer System

Includes:

• Two (2) fermenters

• One (1) BBT conditioning tank for

conditioning and carbonation

• Beer Blender and Keg Washer

• Water purification system

• Glycol Cooling System

• Computer Control System

Features:

• System fits in a 12 x 20 space

• Brewing capacity:

• 68 kegs per month / 8,000 pints (16 oz)

• Operated by 1.5 brewery staff

Beautiful and built to last and keep producing profits long term, year after year, after year!

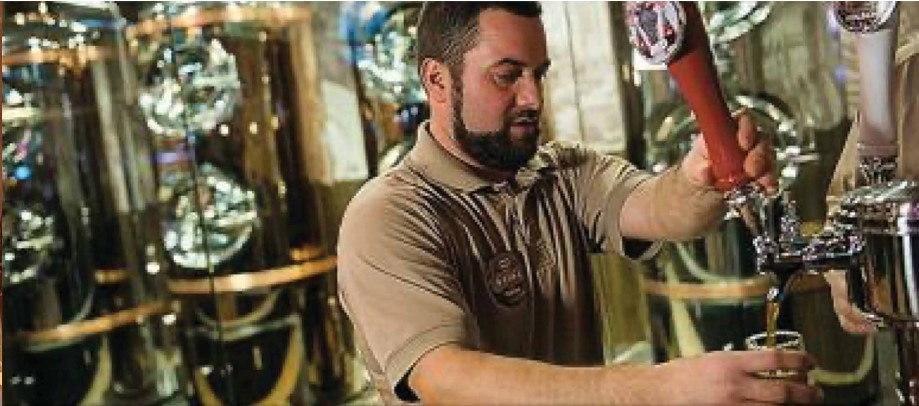

Operational Simplicity and Efficiency

Our fermenters and brite tanks are visually appealing, attracting patrons and serving as excellent front-of-house advertisements. We train a HausCraftBeer Technician and one part-time support person, eliminating the need for a BrewMaster. Your employee can be a bar back or helper.

Environmental Friendliness

Traditional breweries often use between 7 and 10 gallons of water per gallon of craft beer. Hauscraft can make 1 gallon of beer with just 1.5 gallons of water. Our patented bag-to-bag process eliminates the need for caustic chemicals to sterilize fermenter tanks, significantly reducing water consumption and making our process environmentally friendly. After fermentation, bags are simply removed, folded, and discarded.

Versatility

HausCraftBeer Systems can produce a wide range of craft beers, including non-alcoholic options and Kombucha. We offer over 500 yeast strains from WhiteLabs and assist in developing beer styles and flavors to launch your brewery.